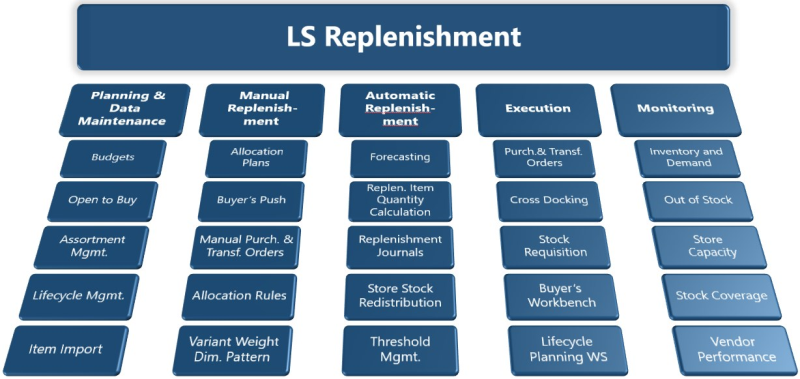

Automatic Replenishment is part of the LS Replenishment suite and is fully integrated in LS Central.

LS Replenishment is a key component in LS Central as it ensures that the right items are at the right place at the right time.

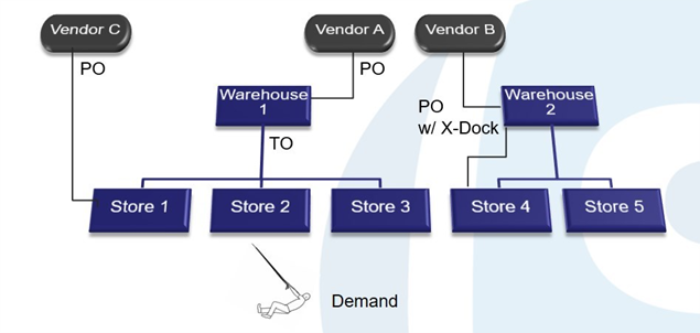

The LS Replenishment system calculates the quantity needed at the stores or the central warehouse and suggests what needs to be purchased from the vendors. It will also help with the distribution of items from a central warehouse to stores when the order arrives at the central warehouse (Planned Cross Docking).

LS Replenishment offers you the option to replenish warehouses and/or stores by way of Purchase Order documents and/or Transfer Order documents.

The Replenishment processes for Automatic Replenishment are executed at the Head Office and the system can suggest the quantity to replenish according to different calculation types or methods. It is also possible to manually allocate quantities to be distributed to the stores. The different Replenishment calculation types and their associated parameters are set up in the Retail Item Card but it is also possible to define overrides for certain items and locations.

The purpose of Automatic Replenishment is twofold:

- To assist the purchasing department with Purchase Order suggestions.

- To assist the store service department with Transfer Order suggestions.

The suggestions are based on different calculation methods and consider the current stock situation in the stores and the warehouses.

Automatic Replenishment is demand driven and supports three ways of item supply to the stores.

Items can be provided to the stores by:

- Direct delivery from the vendor to the store (see image and setting for Vendor C).

In this scenario the Purchase Orders are to be delivered directly to the stores. This is often used at companies without warehouses or for items with a very short durability (bakery products, for example), where a two-step delivery (vendor to warehouse and warehouse to store) would negatively effect the quality of the product. - A two-step approach

Here the items are purchased from the vendor and put into a warehouse first. In a second step, the items are transferred from the warehouse to the stores (see image and setting for Vendor A). In this scenario the purchased items are not assigned to the destination stores at the time of purchase. The purchase flow and the transfer flow can be seen as two separate workflows, even though they are triggered by the same demand and stock information. - A two- step approach, with Cross Docking

Here the items are purchased from the vendor and put into a warehouse first. At the time of the Purchase Order creation, the destination stores are already known. This information is stored in the system as Cross Docking information. In a second step, the items are transferred from the warehouse to the stores (see image and setting for Vendor B). The purchase flow and the transfer flow can be seen as two separate workflows, but they are triggered by the same demand and stock information and the transfer quantities and destinations are already defined in the first step.

The Automatic Replenishment is a toolset to calculate the quantity needed at the stores and the central warehouses. Automatic Replenishment comes with different calculation types for the Purchase Order and Transfer Order proposals:

Main processes:

| To | See |

|---|---|

| Set up the Warehouses, Stores, and Items for Automatic Replenishment. | Basic Setup |

| Understand the Replenishment calculation process. | Replenishment Process |

| Set up Replenishment templates and batches. | Replenishment Template

Replenishment Batch |

| Work with Replenishment journals. | Replenishment Journals

Check result in Calculation Log Lines Create Purchase/Transfer Orders |

| Understand the Replenishment calculation process when store demand exceeds warehouse stock. | Replenishment Transfer Rule |

| Understand the Multi-Company Replenishment concept. | Multi-Company Replenishment |

| Understand the Master Child Replenishment concept. | Master Child Replenishment |

Additional processes:

| Process | Function |

|---|---|

| Store Stock Redistribution | To calculate Transfer Orders to replenish store locations from other store locations. See: Store Stock Redistribution |

| Transfer and Purchase Thresholds Management | To reduce transportation and handling cost by avoiding Purchase Order and Transfer Order proposals that exceed predefined thresholds. See: Transfer and Purchase Thresholds |

| Sales History Adjustment | To correct a biased sales history or simulate a sales history for new items and/or locations. See: Sales History Adjustment |

| Replen. Planned Sales Demand | To manage future changes in demand due to events, discounts or budgets. See: Replen. Planned Sales Demand |

See Also

Replenishment Implementation Guide